Smart Info About What Is G3 Continuity

G3 Continuity

1. Understanding the Basics of G3 Continuity

Ever wondered how some surfaces look so incredibly smooth, like they've been crafted by a magician instead of a machine? A big part of that magic lies in something called G3 continuity. Now, before your eyes glaze over, don't worry! We're not diving into a complex math textbook. Think of it as the "smoothness standard" in the world of curves and surfaces. It's about how well different pieces fit together, ensuring there are no jarring bumps or abrupt changes. Imagine trying to piece together a puzzle where some edges are sharp and others are rounded that's what not having good continuity looks like!

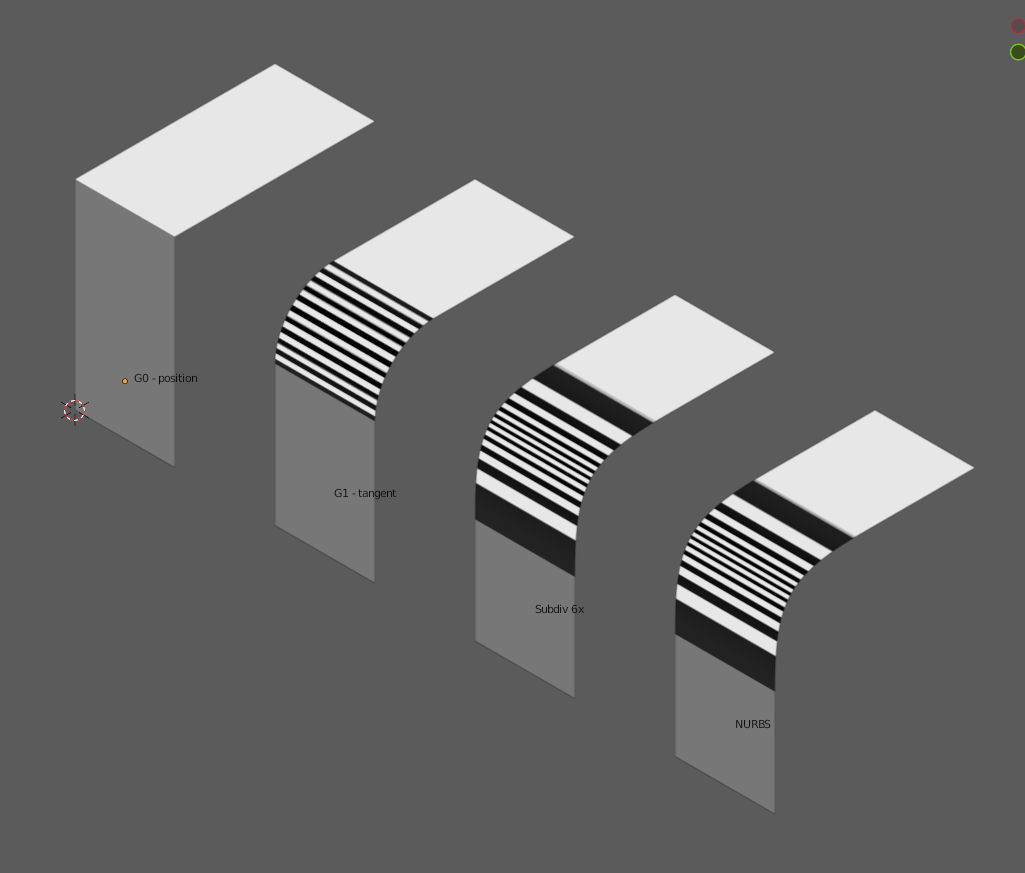

So, what exactly is G3 continuity? It's a level of smoothness that goes beyond just lines meeting up. We're talking about the first, second, and even the third derivatives of the curves matching up at the point where they connect. Think of it like this: G0 continuity means the pieces simply touch. G1 continuity means they touch and have the same tangent (direction). G2 continuity means they touch, have the same tangent, and the same curvature (how sharply they bend). G3? Well, that adds another layer of smoothness, ensuring the rate of change of the curvature also matches! That extra layer of smoothness helps things blend seamlessly and look really polished.

Why does this matter, you ask? Because visual perfection is a valuable commodity! If you are talking about car design, computer graphics, or even designing a sleek toothbrush, you are definitely making sure of this continuity. G3 continuity and beyond helps create objects that are visually appealing and also perform well structurally. Sharp changes in curvature can create weak points, so smoothness also contributes to the durability of the object.

Think of designing a rollercoaster. If the track pieces didn't have a high degree of continuity, the ride would be incredibly jarring and uncomfortable — not to mention unsafe! The smoother the transitions, the more enjoyable (and vomit-free) the experience. G3 continuity is that underlying foundation of a seamless transition.

Math Why Is G3 Continuity Only Achievable Between Two Edges? Stack

Why G3 Continuity Matters

2. The Practical Applications of Smoothness

Okay, we've established that G3 continuity makes things look pretty. But it's not just about aesthetics! There are a bunch of practical reasons why engineers and designers care about this stuff. For example, in manufacturing, surfaces with high continuity are easier to machine and finish. This reduces production time and costs. A smooth surface also results in fewer defects and a longer lifespan of the manufactured part.

In the world of aerodynamics, smoothness is king! Think of the wings of an aircraft. G3 continuity (or even higher) is crucial for minimizing drag and maximizing lift. Any sudden changes in curvature can create turbulence, which reduces efficiency and increases fuel consumption. That is also why planes need to be checked thoroughly after each flight so the continuity remains.

Another example is in medical imaging. When creating 3D models from MRI or CT scans, G3 continuity is often used to smooth out the surfaces. This makes it easier for doctors to visualize and analyze the data. These accurate models can then be used for planning surgeries or creating prosthetics.

Moreover, consider the world of product design. That shiny, sleek smartphone you love? It probably wouldn't look or feel as good if it wasn't for G3 (or higher) continuity. The smooth transitions between surfaces not only make it visually appealing but also make it more comfortable to hold and use. Let's be honest, nobody wants a phone that feels like it's made of jagged edges.

_1657114895.png)

G3 vs. Other Continuities

3. Comparing G0, G1, G2, and G3

Let's break down the different levels of continuity to understand where G3 fits in. As mentioned earlier, G0 continuity means the curves simply touch. There's no guarantee that they blend together smoothly. Imagine two lines meeting at a sharp angle that's G0 continuity.

G1 continuity takes it a step further. It means the curves touch and have the same tangent at the point where they meet. This eliminates sharp corners and creates a smoother transition. Think of a gently curved road that's more like G1 continuity. However, you might still notice a slight change in direction at the point where the curves meet.

G2 continuity goes even deeper. It ensures that the curves touch, have the same tangent, and the same curvature. This creates an even smoother transition than G1. Imagine the transition between two railway tracks as a good example. It's difficult to spot the transition point.

Finally, G3 continuity adds that extra layer of smoothness by ensuring that the rate of change of curvature also matches. This creates an incredibly smooth and seamless transition. It's so smooth that it's often difficult to even notice where the curves connect. It is also a lot better than other continuities.

Applied Sciences Free FullText A G3Continuous Extend Procedure

How is G3 Continuity Achieved?

4. Techniques and Tools for Smooth Surfaces

So, how do designers and engineers actually create surfaces with G3 continuity? It's not like they can just eyeball it! They use a variety of mathematical techniques and software tools to achieve this level of smoothness. One common method is to use Bezier curves and B-spline surfaces. These mathematical representations allow for precise control over the shape and curvature of the surfaces.

Computer-aided design (CAD) software plays a crucial role. These tools allow designers to create and manipulate complex 3D models with high precision. They also provide features for analyzing the continuity of surfaces and identifying any potential problems. The software can automatically adjust the curves and surfaces to ensure they meet the desired level of continuity.

Another important technique is surface modeling. This involves creating a mathematical representation of the surface using a network of curves and patches. The software can then manipulate these curves and patches to achieve the desired shape and smoothness. Imagine it like sculpting a clay model, but on a computer screen.

The whole thing is a highly iterative process. Designers often need to experiment with different techniques and parameters to achieve the desired result. It requires a deep understanding of mathematics, computer graphics, and design principles. And, of course, a keen eye for detail!

G3 Continuity in the Real World

5. From Cars to Consumer Products

Where can you spot G3 continuity in action? Everywhere! The automotive industry is a great example. Car designers use G3 (and higher) continuity to create smooth, flowing lines that are both aesthetically pleasing and aerodynamically efficient. Look at the curves of a modern sports car you'll notice how seamlessly the different panels blend together.

Consumer products are another area where G3 continuity is common. From the shape of a shampoo bottle to the design of a coffee maker, manufacturers use smooth surfaces to create products that are both visually appealing and comfortable to use. Ever noticed how some products just feel "right" in your hand? That's often thanks to careful attention to surface continuity.

Even in architecture, G3 continuity is playing an increasing role. Modern buildings often feature complex curved surfaces that require a high degree of smoothness. This not only creates a visually striking appearance but also improves the structural integrity of the building.

Another example is the design of aircraft interiors. Smooth surfaces are important for creating a comfortable and relaxing environment for passengers. G3 continuity is used to ensure that the different components of the interior blend together seamlessly.

Surface Continuity Architect Students

FAQ

6. Your Questions Answered

Still have questions about G3 continuity? Here are some common ones:

Q: Is G3 continuity always necessary?

A: No, not always. The required level of continuity depends on the specific application. For some applications, G1 or G2 continuity may be sufficient. However, for applications where smoothness and aesthetics are critical, G3 continuity or higher is often preferred.

Q: What's the difference between G3 and C3 continuity?

A: This is where things get a little technical. "G" stands for geometric continuity, while "C" stands for parametric continuity. G3 continuity focuses on the shape of the curve, while C3 continuity focuses on the mathematical representation of the curve. G3 continuity allows for more flexibility in the parameterization of the curve, while C3 continuity requires a more strict mathematical relationship. Think of G as "looks smooth" and C as "is mathematically smooth". Often, G is what people are practically aiming for.

Q: What software is used to achieve G3 continuity?

A: Many CAD and 3D modeling software packages support G3 continuity, including Autodesk Alias, Dassault Systmes CATIA, and Siemens NX. These tools provide features for creating, analyzing, and manipulating surfaces with high precision.