Lessons I Learned From Tips About Are Breadboards Durable

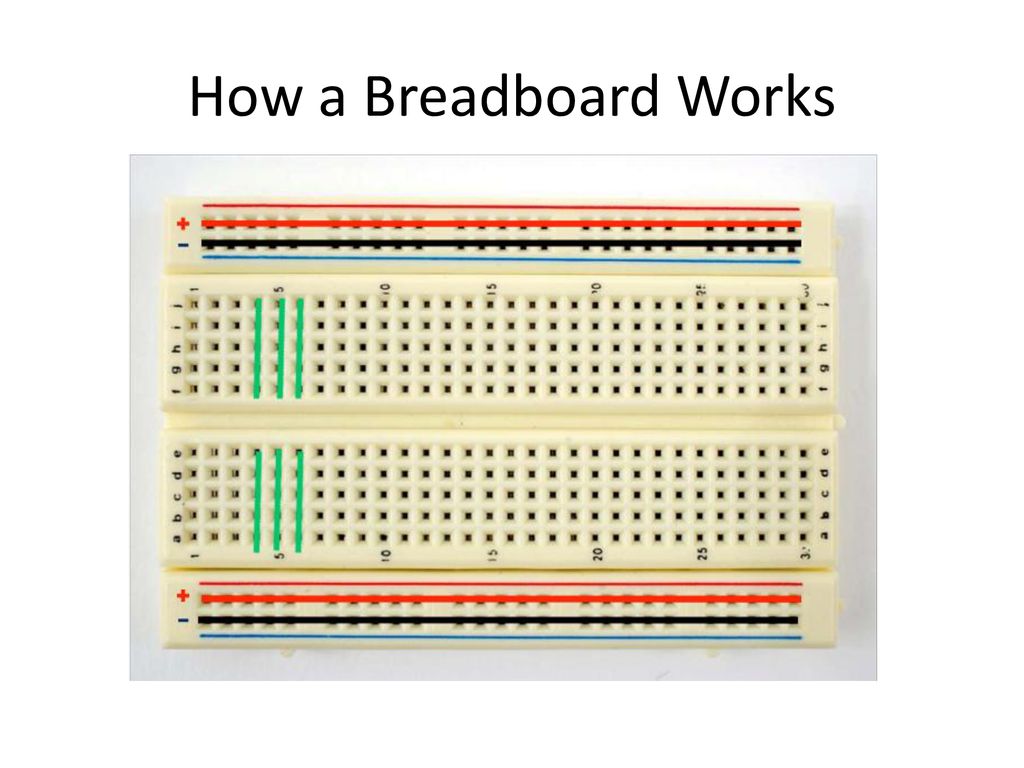

Breadboard How It Works

Breadboards

1. Understanding Breadboard Durability

Let's be honest, when you first pick up a breadboard, "durable" might not be the first word that springs to mind. They're lightweight, often made of plastic, and those little holes just look begging to be damaged. But are breadboards really as fragile as they seem? The answer, like most things in electronics, is a bit more nuanced than a simple yes or no. Think of them less like a hammer and more like a, well, a specialized piece of plastic designed for prototyping.

The durability of a breadboard hinges on several factors, including the quality of its construction, how it's used, and the environment it's kept in. Cheaper breadboards, predictably, tend to be less durable. They might use thinner plastic, lower quality metal contacts, and generally be more prone to wear and tear. On the other hand, higher-quality breadboards are built to withstand more abuse, both physical and electrical.

One of the biggest enemies of breadboard longevity is repeated insertion and removal of components. Each time you jam a resistor or LED into those tiny holes, the metal contacts inside get a little bit more stressed. Over time, this can lead to the contacts loosening, resulting in poor connections and frustrating debugging sessions. It's like repeatedly bending a paperclip — eventually, it's going to snap.

Finally, the environment matters! Exposing your breadboard to extreme temperatures, humidity, or direct sunlight can accelerate its degradation. Think of it like leaving your phone in a hot car — not a recipe for long-term health. Keeping your breadboard clean and stored in a cool, dry place will significantly extend its lifespan. Handle them carefully and they can last for quite a while.

The Achilles' Heel

2. Addressing Contact Degradation in Breadboards

The single most vulnerable aspect of a breadboard is, without a doubt, the quality of its internal contacts. These tiny metal clips are the unsung heroes (or villains, depending on your perspective) of any breadboard circuit. They're responsible for making a reliable electrical connection between your components, and when they fail, your project goes haywire.

The problem with the contacts is that they're designed to be "springy," allowing them to grip the leads of components of varying thicknesses. However, this springiness can degrade over time, especially with frequent use. Imagine stretching a rubber band repeatedly — eventually, it loses its elasticity and becomes loose. The same thing happens to the metal contacts in a breadboard.

Poor contact quality manifests in a variety of ways. You might experience intermittent connections, where your circuit works sometimes but not others. You might also find that certain components require excessive force to insert, indicating that the contacts are already damaged. In severe cases, the contacts might break entirely, rendering that particular hole useless.

So, what can you do to protect your breadboard contacts? First, avoid using components with excessively thick leads. These can stretch the contacts beyond their elastic limit, causing permanent damage. Second, be gentle when inserting and removing components. Avoid twisting or wiggling them, as this can accelerate wear and tear. And finally, if you suspect a contact is failing, try using a different hole before condemning the entire breadboard.

Abuse and Misuse

3. Common Mistakes That Shorten Breadboard Life

We've talked about inherent weaknesses, but let's be honest, a lot of breadboard damage is self-inflicted. Just like any tool, a breadboard can suffer from abuse and misuse. Think of it like a car — even a well-built vehicle will break down if you drive it recklessly and neglect maintenance. Breadboards aren't exactly cars, but the principle holds true.

One of the most common forms of breadboard abuse is applying excessive force. We've all been there — wrestling with a stubborn component, pushing and shoving until it finally clicks into place. But each time you do that, you're potentially damaging the delicate contacts inside the breadboard. A gentle, steady pressure is always the best approach.

Another frequent mistake is using components with the wrong lead size. Breadboards are designed for standard-sized component leads. If you try to force in something that's too thick, you'll likely damage the contacts. Conversely, if you use something that's too thin, it might not make a reliable connection. Make sure you're using the right components for the job.

Finally, neglecting basic maintenance can also shorten your breadboard's lifespan. Dust, dirt, and debris can accumulate in the holes, interfering with electrical connections. Regularly cleaning your breadboard with compressed air or a soft brush can help prevent these problems. It's like brushing your teeth — a little bit of preventative care goes a long way.

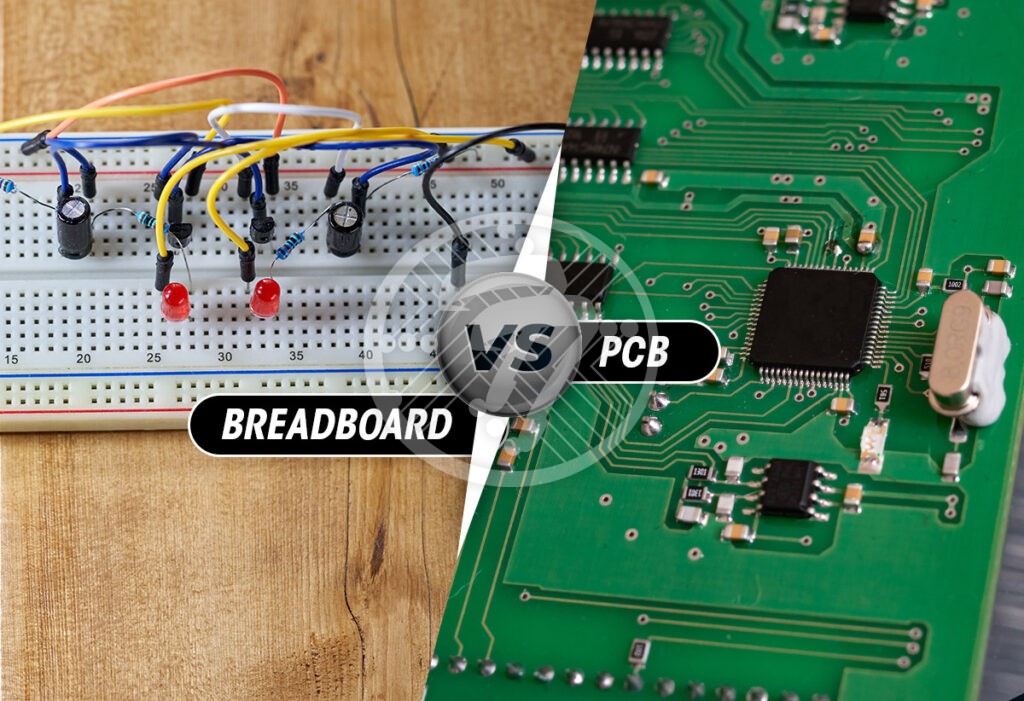

PCB Vs Breadboard Technotronix

Extending the Lifespan

4. Practical Ways to Keep Your Breadboard Happy

Okay, so we've established that breadboards aren't indestructible. But don't despair! With a little care and attention, you can significantly extend the lifespan of your breadboard and avoid those frustrating connection issues. Think of it as adopting a pet — a little effort will be rewarded with years of companionship (or, in this case, reliable prototyping).

One of the simplest things you can do is to use solid-core wire for your connections. Solid-core wire is much easier to insert and remove from the breadboard than stranded wire, and it's less likely to damage the contacts. Plus, it tends to stay in place better, reducing the risk of accidental disconnections. You can find assortments of pre-cut and stripped solid-core wire specifically designed for breadboarding.

Another helpful tip is to label your connections. This might seem like overkill, but it can save you a lot of time and frustration in the long run. Use colored tape or labels to identify different components and wires. This will make it much easier to debug your circuit and prevent accidental misconnections. It's like labeling your spice rack — you'll be surprised how much time it saves.

When storing your breadboard, keep it in a clean, dry place away from direct sunlight and extreme temperatures. A plastic storage container works well for this purpose. You can also use a desiccant packet to absorb any excess moisture. This will help prevent corrosion and extend the life of the metal contacts. Think of it like storing your winter clothes — you want to protect them from the elements.

If you are finding the connections are getting looser, avoid those pins and find new ones. Over using same pin can lead to permanent damage, it is like repeatedly bending a wire which cause weaken it over time.

How To Use A Breadboard Build Circuits Fast & Easy

Breadboard Alternatives

5. Evaluating Alternatives to Breadboards for Durable Projects

Despite your best efforts, there comes a time when a breadboard simply isn't the right tool for the job. If you're building a circuit that needs to be robust and reliable, or if you're planning on using it for an extended period of time, it's probably time to consider alternatives. Think of it like graduating from training wheels on a bicycle — eventually, you need to move on to something more advanced.

One popular alternative is stripboard (also known as Veroboard). Stripboard consists of a grid of holes with parallel strips of copper running along one side. You can solder components directly to the copper strips, creating a permanent and reliable connection. Stripboard is a great option for small to medium-sized circuits that need to be durable.

Another option is perfboard. Perfboard is similar to stripboard, but it doesn't have any copper strips. This gives you more flexibility in terms of component placement and wiring. However, it also requires more soldering, as you need to create all of the connections yourself. Perfboard is a good choice for complex circuits that require a high degree of customization.

For more complex and professional projects, consider designing a custom printed circuit board (PCB). PCBs are manufactured using a process called photolithography, which creates a precise and durable circuit board with all of the components soldered in place. Designing a PCB requires specialized software and knowledge, but it's the best option for creating a high-quality, reliable circuit. Think of it like building a house instead of camping in a tent — it's a more involved process, but the results are much more permanent and satisfying.

FAQ

6. Your Burning Breadboard Questions Answered

Still got questions about the lifespan and durability of your trusty breadboard? No sweat! Here are a few common questions, answered with a dash of practical advice and a sprinkle of humor.

Q: How long should a breadboard last?A: That's like asking how long a lightbulb will last — it depends! A good-quality breadboard, treated with care, could easily last for several years. A cheap one, abused and neglected, might give up the ghost after a few months. Regular cleaning and avoiding excessive force will definitely extend its life!

Q: Can I repair a damaged breadboard?A: In some cases, yes! If a single contact is damaged, you can sometimes use a small screwdriver or needle to carefully bend it back into shape. However, if multiple contacts are damaged, or if the plastic housing is cracked, it's probably time to invest in a new breadboard. Think of it like trying to fix a flat tire — sometimes it's worth the effort, but sometimes it's just easier to buy a new tire.

Q: What's the best way to clean a breadboard?A: Compressed air is your friend! Use it to blow out any dust, dirt, or debris that has accumulated in the holes. You can also use a soft brush to gently scrub the surface of the breadboard. Avoid using liquids, as they can damage the metal contacts. It's like cleaning your computer keyboard — a little bit of preventative maintenance will keep it running smoothly.

Q: Are solderless breadboards durable?A: The keyword “durable” is an adjective. Compared to soldering, solderless breadboards are less durable when building complex circuit but more durable in terms of usage time. In other words, durable, in this context, meant it’s easily to be replace if something gone wrong.